There are three main design approaches for excavation in rock

Analytical Method

Observational Method

Empirical Method

The most predominant design approach is the empirical design method.

Analytical methods:

Utilizes the analysis of stresses and deformations around openings.

E.g. closed form solutions, numerical methods (finite elements, finite differences), analog simulations (photo-elastic).

Observational design methods:

Rely on actual monitoring of ground movement during excavations to detect measurable instability and on the analysis of ground-support interaction.

The observational method is a way to check other methods.

Empirical design methods:

These methods asses the stability of mines and tunnels by the use of statistical analysis of underground observations.

For example engineering rock mass classifications.

Rock mass classification:

Rock mass classification schemes are Empirical approaches to Excavations design, in particular for determining support requirements. So it is a "trial-and-error" procedure

Rock mass classification schemes have been developing for over 100 years since Ritter (1879) attempted to formalize an empirical approach to tunnel design, in particular for determining support requirements.

Objectives:

Identify the most significant parameters influencing the behaviour of a rock mass

Divide a particular rock mass formulation into groups of similar behaviour – rock mass classes of varying quality

Provide a basis of understanding the characteristics of each rock mass class

Relate the experience of rock conditions at one site to the conditions and experience encountered at others

Derive quantitative data and guidelines for engineering design

Benefits of rock mass classifications:

Improving the quality of site investigations by calling for the minimum input data as classification parameters

Providing quantitative information for design purposes

Enabling better engineering judgement and more effective communication on a project

List of rock mass classifications:

Different classification systems place different emphases on the various parameters, and it is recommended that at least two methods be used at any site during the early stages of a project.

Rock Quality Designation index (RQD)

Rock Structure Rating (RSR)

Geo mechanics Classification or the Rock Mass Rating (RMR) system

Tunnelling Quality Index (Q system)

Terzaghi's rock mass classification

Rock Structure Rating (RSR):

Wickham et al (1972) described a quantitative method for describing the quality of a rock mass and for selecting appropriate support on the basis of their Rock Structure Rating (RSR) classification.

The significance of the RSR system, is that it introduced the concept of rating each of the components listed below to arrive at a numerical value of RSR = A + B + C.

A) Parameter A, Geology: General appraisal of geological structure on the basis of:

a. Rock type origin (igneous, metamorphic and sedimentary).

b. Rock hardness (hard, medium, soft and decomposed).

c. Geologic structure (massive, slightly faulted/folded, moderately faulted/folded, intensely faulted/folded).

B) Parameter B, Geometry: Effect of discontinuity pattern with respect to the direction of the tunnel drive on the basis of:

a. Joint spacing.

b. Joint orientation (strike and dip).

c. Direction of tunnel drive.

C)Parameter C: Effect of groundwater inflow and joint condition on the basis of:

a. Overall rock mass quality on the basis of A and B combined.

b. Joint condition (good, fair, poor).

c. Amount of water inflow (in gallons per minute per 1000 feet of tunnel).

Figure 4: RSR support estimates for a 24 ft. (7.3 m) diameter circular tunnel. Note that rock bolts and shotcrete are generally used together. (After Wickham et al 1972).

Geo mechanics Classification:

Bieniawski (1976) published the details of a rock mass classification called the Geo mechanics Classification or the Rock Mass Rating (RMR) system. This system is used in wide engineering practise involving tunnels, chambers, mines, slopes, and foundations.The Geo mechanics Classification has found wide applications in various types of engineering projects such as;

Tunnels

Slopes

Foundations

Mines

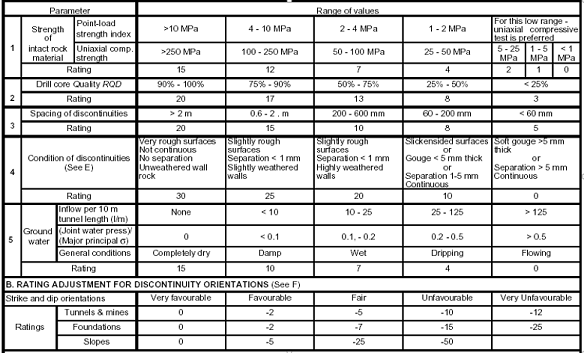

The following six parameters are used to classify a rock mass using the RMR system:

1. Uni axial compressive strength of rock material.

2. Rock Quality Designation (RQD).

3. Spacing of discontinuities.

4. Condition of discontinuities.

5. Groundwater conditions.

6. Orientation of discontinuities.

In applying this classification system, the rock mass is divided into a number of structural regions and each region is classified separately. The boundaries of the structural regions usually coincide with a major structural feature such as a fault or with a change in rock type. In some cases, significant changes in discontinuity spacing or characteristics, within the same rock type, may necessitate the division of the rock mass into a number of small structural regions.

CLASSIFICATION PARAMETERS AND THEIR RATINGS

ROCK MASS CLASSES DETERMINED FROM TOTAL RATINGS:

Guidelines for excavation and support of 10 m span rock tunnels in accordance

with the RMR system (After Bieniawski 1989):